SCADA Canal Operator Training Tool (AZ)

The Central Arizona Project (CAP) is a 336-mile long system of aqueducts, tunnels, pumping plants, and pipelines that is designed to bring about 1.5 million acre-feet of Colorado River water per year to Maricopa, Pima, and Pinal counties in Arizona. The entire CAP system is remotely monitored and controlled using Supervisory Control and Data Acquisition (SCADA) software from CAP headquarters in Phoenix, AZ. As of July, 2008, several new SCADA operators had been hired by CAP. In the past, the new operators received SCADA training only by observing the more experienced operators manage the canal system; thus their lengthy training was driven only by the day-to-day operation of the system.

To better equip their new SCADA operators, personnel at CAP commissioned the development of a new SCADA training tool as envisioned by researchers at the U.S. Arid Land Agricultural Research Center that replaces the real canal system with a hydraulic simulation model without making any changes to the SCADA software. Employees at WEST Consultants, Inc. modified this training tool so that it works with HEC-RAS (developed by the U.S. Army Corps of Engineers) as the unsteady hydraulic simulation model. Using this training tool, the new SCADA operators are now being trained to operate the CAP system under a much wider range of flow conditions and emergency situations without endangering the actual canal system. This type of training will reduce the time required to train operators and enable the operators to route flow changes more efficiently through the CAP system, and give the operators a larger knowledge base with which to handle emergency situations.

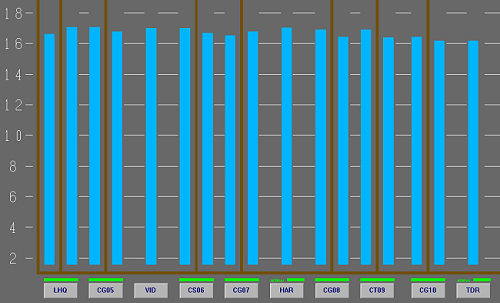

This training tool was developed for Segment 2 of the CAP canal system, which stretches 62 miles from the Little Harquahala pumping plant to the Hassayampa pumping plant. This stretch of the CAP system includes nine check structures (each with two radial gates), three pumping stations, and five customer delivery turnouts. All of these components were included specifically into the development of the HEC-RAS unsteady hydraulic simulation, even including custom gate calibrations developed by CAP for each radial gate. WEST personnel then reproduced individual SCADA screens for the canal and each of the individual structures to replicate screens seen by the SCADA operators controlling the actual CAP system. Through these screens, operator trainees could interact with the hydraulic simulation model by adjusting the levels of the gates, the control of each individual pump in every pump station, and the flow deliveries at each customer turnout. As adjustments are made to the canal system, the hydraulic simulation model sends information back to the SCADA screen displays such as water levels and flows.